Wishbone Center

Since the beginning of 2015 Rodrunner continues all of its wishbone production activties in the new 5000 m² closed area within the factory.

With its experience in the sector, culture of quality and the increasing investments made to special processes, Rodrunner has the privelage to be the pioneer of wishbone production and, at the same time, a solution partner for all of its customers.

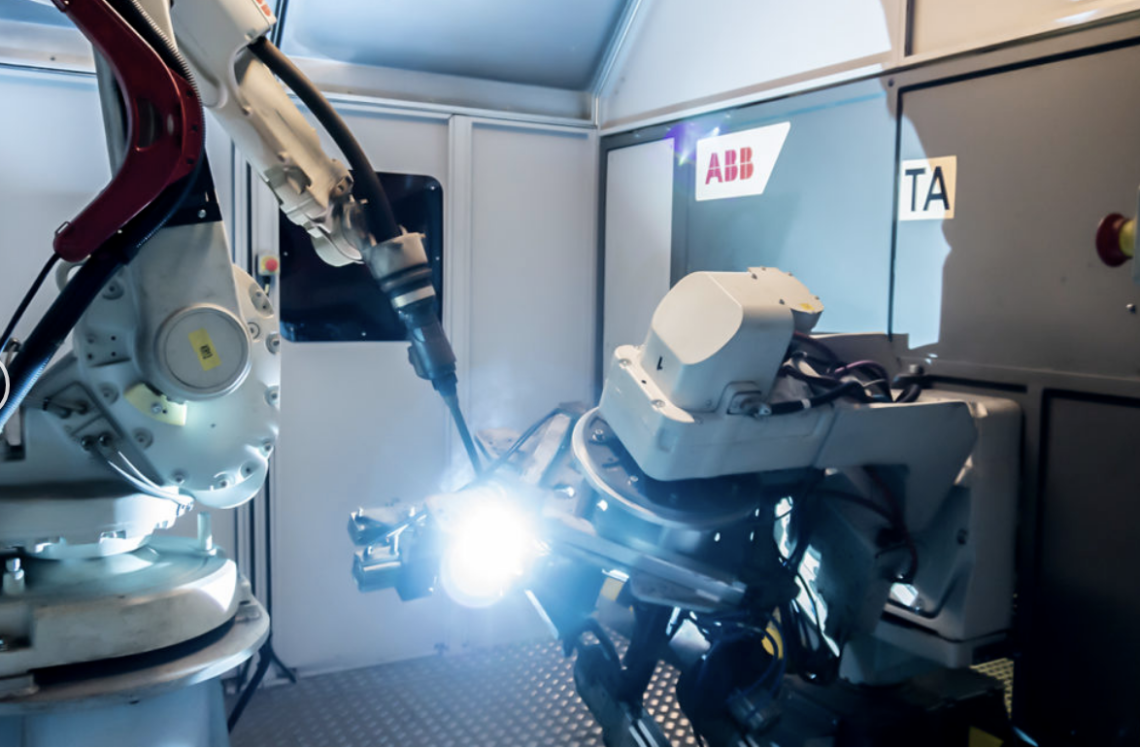

Rodrunner continues to meet customer commintents of high quality and on time delivery by producing with 10 Robot welding lines and servo-controlled ball joint and bushing presses.

We are well aware that our products are safety critical items for the end users and aim to achieve always better results while improving our processes. In this context we know the importance of the welding processes in wishbone production. With the CMT Integrated Welding Robots, which started operating in 2016, Rodrunner once again proved it’s difference from the sector and continue to produce in OEM quality standards.

The process standardization is secured with our Servo-controlled ball joint and bushing press parks. We are able to pack form for customers through our lean manufacturing single-band assembly-packaging lines.